| The toolbox | |||||

| Orvo Valila on deep sump & high capacity oil pump installation | |||||

| All of us

brave Chang riders at one time or another must have

stumbled across a problem of insufficient lubrication in

our dear but ah-so-unreliable engines. That bitty sump

and small-volume oil pump may have been plenty enough for

1930’s roads and speeds (though I kinda doubt even

that) but for any speeds over 60 km/h there simply is

just not enough oomph in the lubricating system of a CJ.

Some of us have learned this in the very hard way via

seized pistons and damaged cylinders, as we have learned

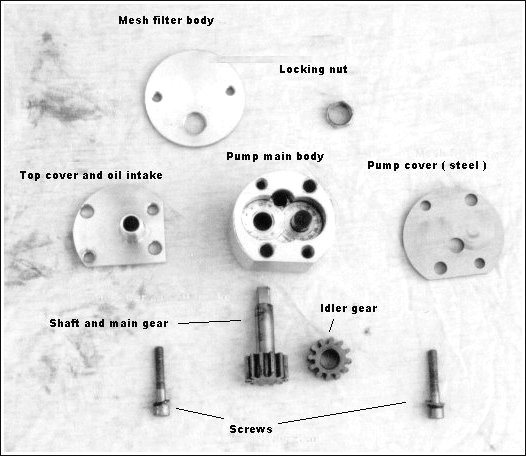

in these pages. Yours Truly including. Therefore it is surely not surprising that some of the most popular and truly needed CJ and M-72 modifications are different improvements in lubrication. Personally I’ve seen all kinds of weird and wonderful things like external belt-driven hi-tech oil pumps and VW Beetle oil pump replacements which, I’m sure are a huge improvement over the original ones. These tailor made improvements however come with no small cost of design work and elbow grease. But where there is a will there is always a way. Lucky for us slightly less engineering-orientated that are not capable of McGyvernean heroics like repairing nuclear power plant with duct tape and paperclip, there are also simpler bolt-on type conversions available. Dong Tian Enterprises for example have been offering for a while deeper oil sumps and hi volume oil pumps and there are plenty more dealers that can be found over the Web. Sure enough, after replacing second set of pistons in my CJ, I thought it would be time to do something about the issue. Dong Tian version of the oil pump seems okay and their deep sump is very nice indeed. Somehow though being more or less familiar with the legendary quality of CJ and its siblings, the idea of replacing a Chinese pump with another one did not really seem all that appealing to me. So instead I thought that I try to get the better of two worlds and get the deep sump from Dong Tian and a Hi-Tech custom made pump from Eckhardt Schulz. The Schulz pump is not exactly a cheap one (delivered $135), but neither is replacing pistons all the time so I thought I’d give it a go. Lucky enough, at the same time, a colleague was visiting Beijing to take care of the sump delivery. So I ordered the pump, which was relatively painless except for a small delay due to confusion in the stock. Turned out I got the only one they happened to have in stock at that time. Anyway, I was well prepared and not in a hurry as the schedule was to install the pump during my vacation in Finland, where the bike is currently located. The pump arrived at the agreed time and all went smoothly according to plan (though my mother-in-law was wondering whether I was involved in international drug trafficking with this suspicious looking package from South Africa…;-) Enter me, eager to get this show on the road and to see whether this would really make a difference or not. Like a kid in Christmas I ripped open the package and started to examine the pump. First surprise: the pump would not rotate?? Well, I thought, it is probably just stuck with some dried cutting oil inside after being stored. Nothing that a little WD-40 and some wiggling would not fix. To the garage then. Squirt of oil and careful try with an 8mm spanner… there you go. Problem solved, thought I. Until I peeked into the pump while rotating the shaft. What the…?? The shaft rotates but not the gears inside??? Just my luck again I

thought. Well, nothing to lose any more, I might as well

take the whole pump apart. And so I did:

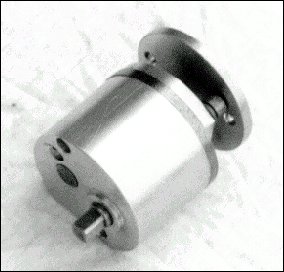

After ventilating all the blue air out of the garage and a calming cigarillo I started examining the problem closer and noticed that curiously enough, not only the main gear was loose fit but also the idler gear was tight in its own shaft. Loose gear, tight gear…hmm… wait a minute… maybe??…but of course!! The gears were swapped for some reason!! I quickly tried the loosen main gear as the idler and it was just perfect. Then I tried the other gear on the shaft and it would not quite slide on it. I rigged the whole thing in a vise and pressed the shaft into the gear. Hey Presto!! Perfect fit. So I re-assembled the pump, fixed it into a cordless drill and tried it out over a can of oil. Beautiful squirt of flowing oil! Just to make sure I was running the pump for a 10 minutes or so with oil and then took it apart and cleaned everything once again with carburetor cleaner to get rid of all the burrs and shavings. Good Lord knows that there is already enough of that stuff in a CJ engine… Pump is ready for

installation and all is well again.

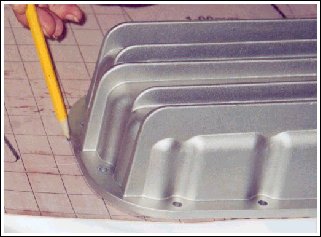

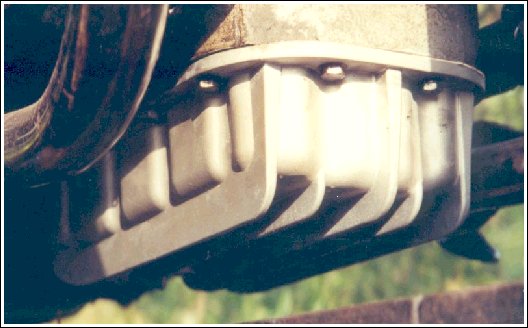

Dong Tian sump is as a

matter of fact pretty impressive with the cooling fins

and all. ...

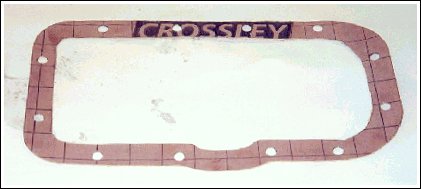

To the bike then. After securing the bike on a sturdy car ramp doubling as a grease pit, I bravely ducked under the beast. Being advised by more experienced colleague again, I had already reserved slightly longer screws for the new sump, as the old ones supposingly are barely long enough to reach first few threads with the deeper sump. However as I removed the old screws and sump (yes, after draining what was left of the oil in there…) I noticed that even the old screws would have been long enough unlike in my buddy’s bike?? Irregularities in Nangchang production quality?? Really?? Well, Mei Guanxi says the Chinaman, which roughly translates "Who cares?" As I very successfully

managed to increase my reputation as a remarkable

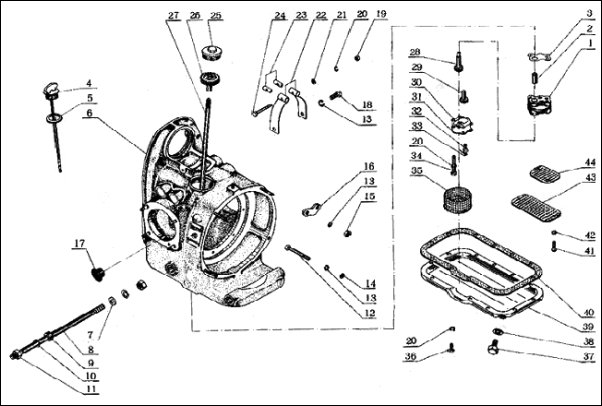

photographer by ruining most of the pictures of the old

pump in place, I thought a little schema here would be

very educational. Most of you are already well familiar

with this one.

After that, when you figure out that the shaft cannot be simply reinserted, but instead you have to remove the gear and cap (25) and reconstruct the whole wobbly contraption at both ends at the same time, more cusswords are usually heard. And in my case were, in Finnish again. I probably should not have, though. Immediately as a punishment of my blasphemous language a huge rain/hail shower drove me back to the shelter of the garage to repent my heretic act and sacrifice another cigarillo as an offering. So. Lesson learned. Before removing the pump, open the cap, remove the gear and somehow secure the shaft in its place. Saves you from lots of grief and a possible thundershower. Replacing the pump itself then is a piece of cake, and securing the mesh filter to the interesting asymmetric adjustable baseplate is hardly any more difficult. Just make sure that the plate is in the right position that the sump can be fitted in place without the mesh filter touching on the side. And finally with the sump

installed, all the screws tightened (with Loc-tite, mind

you. This baby shakes.) ….TA-DA!!

Beautiful! Sits tight, doesn't leak and is ready to go. One worry though. In the old shallow sump the drain plug is at the rear end of the sump, pointing more or less towards the rear wheel. This, I thought previously, is a perfect place for an oil temp gauge sensor. And it is. However, with this new deep sump there is even less ground clearance. And woeth me, the drain plug is directly down now?! That means that between my precious temp gauge sensor and ground there is not too much clearance for comfort. That probably will be the next mod for my CJ as it really is a low rider now. More than likely I need to drill an additional hole on the rear of the sump facing backwards and thread that for the sensor, and replace the drain plug with the original one. However my schedule did not allow that mod to be done at this time as we were supposed to leave to the rally early next morning and I did not have the right tools anyway. Moment of truth. Does it work? Come to think of it…how do I know whether it works or not? There is no oil pressure light (hardly any oil pressure either with all the roller bearings in there…) Oh well, I thought, there is only one way to find out. Start the engine and see what happens. And so I did. Runs nice… well as nice as it can anyway… no suspicious clanking or any other noises. Gear on, on the road carefully. Still nice, after a while no sign of oil temperature (scale begins at 40°C.) Well. As it was getting

late and the true nature of the mod would be revealed

only on the long run, there was nothing else to do but to

get ready for the trip for the next morning.

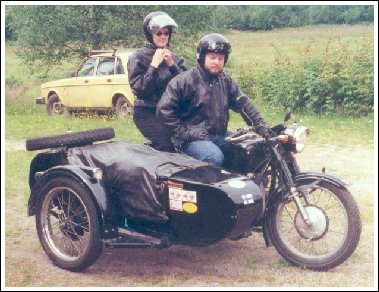

This in the 80 km/h marching speed, us both on and sidecar full of bee….err…supplies. Encouraged of this, I fearlessly went for reckless 90 km/h. Still no problems, sounding sweet and oil temps below 90°C. Previous experience is that even with good quality oil, when the temperature hits 120°C mark, you have about 15-min. piston life left if you do not slow down. So plenty of margin there. To the magic incredible 100 km/h mark. Unbelievable!! Half an hour of that and oil temp nowhere near 100°C!! This with a CJ is nothing short of a miracle!! BTW I probably need to note here that the bike is also modified with 3.89:1 final gear ratio, and the speedo is dead anyway, so I’m using GPS for my speed. So even in my euphoric state of mind I do not believe I was hallucinating much what it comes to speeds. Summa summarum. Was it worth the trouble? Definitely. Was it worth the money? Seems to save the pistons? Is it recommended? Hell yes!!! And next maybe the long ratio 4th gears…and then I probably need to do something to improve the brakes…and then… oh well. It’s still a CJ so better not get too carried away….. Cheers! Orvo |

|||||